The hot, toxic, stifling workplace where raincoats and waterproof hats are made.

‘The Oil Clothing Industry’ by An Oiler from The People (S.L.P.). Vol. 9 No. 1. April 2, 1904.

The making of oil clothing is a hard, disagreeable, unhealthy and poorly paid occupation. Oil clothing is mainly used by seamen, miners, motormen and others, who need waterproof garments to protect them from the elements. The cloth used is calico, increased in ply until the desired thickness is reached. The cloth is oiled three times in the color wanted. The oil used in the first covering is a raw linseed. The last is a varnish. After each covering, the clothing is put into a drying room, located directly behind the rooms in which the oiling is done. The drying rooms are usually heated to 115 degrees to 120 degrees Fahrenheit. Here gases evaporate from the clothing. There are doors leading to and from each of these drying rooms from which these gases escape into the adjoining rooms. In the drying rooms the gases form a vapor of a bluish line plainly visible to the naked eye. The oilers turn again and again to the cloths on their tables, using small brushes, their eyes red and swollen from the effects of the evaporated oil, and their chests frequently heaving with the racking cough it compels.

In addition to the infernal physical discomforts caused by the intense heat and the gas from the evaporated oil, the men employed at this occupation are compelled, by the nature of their work, to be dirty and oily. The oil stiffens the garments they wear, impeding their progress. As the men work by piece, in order to facilitate their labor and increase their earnings, they strip until half-naked. The clothing is always oiled in oil of the color desired. Black clothing is the worst to oil. Those working with this oil are, as a result of it and their enforced deshabille, often black from head to foot. Nothing more disagreeable can well be imagined.

The stifling atmosphere causes the men to keep their windows open even in winter, in order to secure fresh currents of air. Despite this measure, the atmosphere remains almost unbearable; and stimulants are often indulged in in consequence..

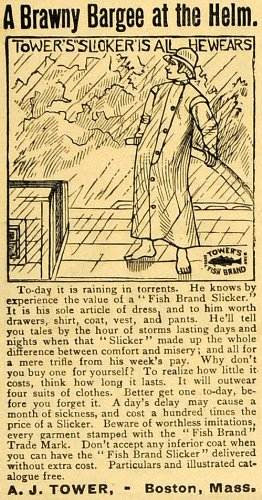

A typical on clothing factory is that of the A.J. Towers Co., at Roxbury, Mass. This company employs 90 men 50 of whom work in the oiling room. There are also about 300 girls employed in the sewing department. The following notices will give an idea of conditions in the Towers Co. factory:

“NOTICE.

“Beginning with March 23, and from this date forward, work in the oil house will be done on the piece system, and the following prices per dozen for finished goods will be paid:

“Clothing.

“Pommels, 42c.; slickers, 36c.; motor coats, 32c.; long coats, 36c.; medium long coats, 32c.; frocks, 32c.; jackets, 27e.; pants, 27c.; glossy coats, 36c.; glossy coats (yellow lined), 53c.; No. 210 slickers, 44c.

“Hats.

“Yellow squam, 18c.; yellow miners’, 18c.; black squam, 19c.; black miners’, 19c.; Cape Ann, 30c.; storm king, 23c.; fish, 32c.; soft, 12c.

“Duck barvells, 18c.; comm., barvells,15c.

“Aprons.

“Horse Goods, “Hame covers, 44c.; hood covers, 48c.; small boots, 40c.; large boots, 42c. “Sign Coats.

“Large, 32c.; min., 16c.

“Per order A. J. Tower Co., “Walter S. Barker, Manager. “Boston, April 7, 1903.”

“NOTICE.

“After this date no payment will be made for poor oiling, and every garment rejected will be deducted from pay check.

“Continuous work is requested during working hours, and loafing will result in discharge.

“A.J. Tower Co.,

“Per Walter S. Barker, Manager. “Boston, October 21, 1903.”

As will be seen by the first notice, the work in this factory is done according to the piece system. Before this system was introduced the workmen were paid by the week. Then each worker had a certain amount of work to perform during the day. Wages varied from seven to ten dollars a week.

The introduction of the piece-work system was opposed by the workers, who went on strike when it was inaugurated.

They regarded piece-work as a “clever” scheme of the capitalist class by which every moment of labor could be intensified and more profitably utilized. This strike lasted two weeks, after which the workers returned to work under the new rules. Such a result was likely foreseen, as the employes are mainly Swedes, unorganized and unfamiliar with the language and customs of the country. Most of them are from the rural districts of Sweden, and came here under the belief that in this “free Republic” “every man is the architect of his own future.” None of them had any knowledge of the class struggle, though they are becoming acquainted with it fast enough.

One of the workers, speaking of the Towers Co. recently, said: “This company issues a beautiful calendar to advertise its goods. This year’s is called ‘A Wreck on the New England Coast.’ The picture shows a ship floundering in the waves, with a boatload of passengers departing from it. On the shore are seen a lot of spectators, wearing the firm’s oil clothing. When I see that picture I say to myself: “If those passengers are Swedes, destined to be exploited in Towers’, they haven’t experienced their final wreck. When they get ashore their dreams will suffer shipwreck, too.”

Recently the company restricted production by curtailing the amount of clothing to be oiled by each worker. This has caused wages to decline to about nine dollars a week. It has also decreased the working time. While the workers certainly desire the fresh air thus gained, they consider the wages hardly sufficient for their physical needs. It is the belief of the employes that the crisis is to blame for this condition of affairs.

These brief lines depict an industry which, like all industries under capitalism, is run for profit instead of use. To this may be attributed the lack of proper mechanical methods of ventilation which make it one of the worst forms of wage slavery. Only when industry is run for social use, instead of capitalist profit, will this condition be altered. And it is the aim of Socialism to bring this about. Roxbury, Mass.

An Oiler.

New York Labor News Company was the publishing house of the Socialist Labor Party and their paper The People. The People was the official paper of the Socialist Labor Party of America (SLP), established in New York City in 1891 as a weekly. The New York SLP, and The People, were dominated Daniel De Leon and his supporters, the dominant ideological leader of the SLP from the 1890s until the time of his death. The People became a daily in 1900. It’s first editor was the French socialist Lucien Sanial who was quickly replaced by De Leon who held the position until his death in 1914. Morris Hillquit and Henry Slobodin, future leaders of the Socialist Party of America were writers before their split from the SLP in 1899. For a while there were two SLPs and two Peoples, requiring a legal case to determine ownership. Eventual the anti-De Leonist produced what would become the New York Call and became the Social Democratic, later Socialist, Party. The De Leonist The People continued publishing until 2008.

PDF of full issue: https://www.marxists.org/history/usa/pubs/the-people-slp/040402-weeklypeople-v14n01.pdf