A worker details the ‘rotten lot’ of workers in Omaha’s meat packing industry, where the ‘Big Four’ ran the city as their own with labor disciplined by paternalism, racism, spies, speed-up and unemployment.

‘Rotten Lot of Workers in Omaha Packing Houses’ from The Daily Worker. Vol. 2 No. 302. January 5, 1926.

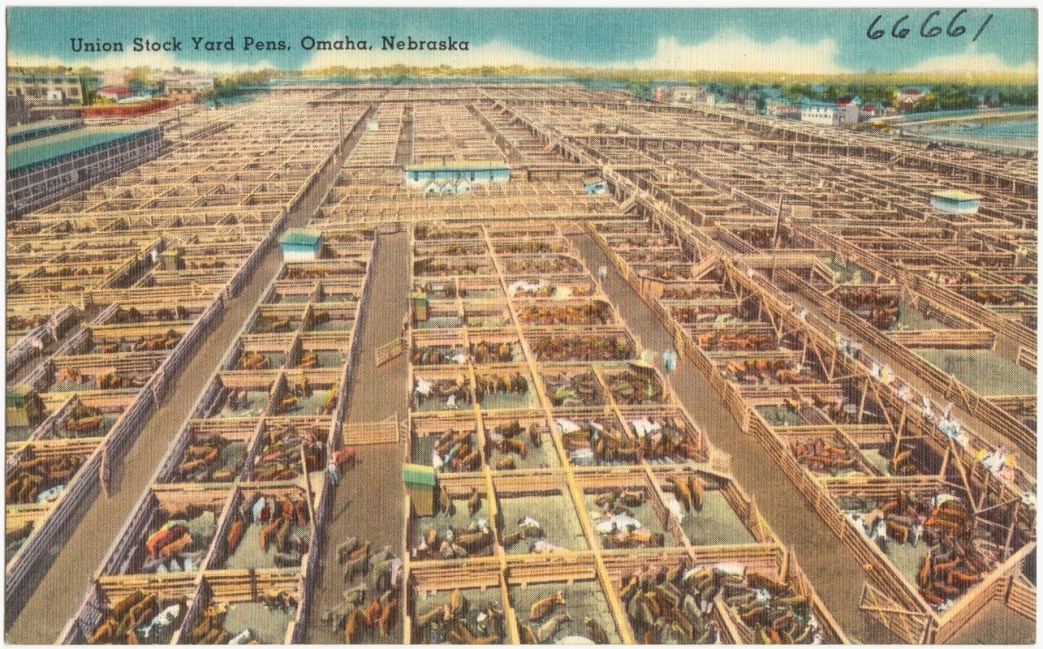

By a Worker Correspondent. OMAHA, Nebr., Jan. 3. We have the “Big Four” packers in Omaha, Armour-Morris, Swift, Cudahy and Dold. Then there are some small plants, South Omaha Packing Co., Mid-West Packing Co., Glossberg Packing Co., Omaha Packing Co. and Fisher & Sons. All the packing plants are located on the south side of Omaha.

Common labor in the yards is paid 42 1/2 cents per hour. Work is from 6 to 14 hours per day. After 45 hours work during any one week, time and one-half is paid for overtime, but it is generally arranged so that no overtime is worked. Much of the work is done by the piece in the packing plants today, with varying prices.

Mostly Negroes.

Most of the workers in the packing houses of Omaha are Negroes. Next come the Polish, Bohemian, South Slavic, with about 4 per cent Mexicans work outside the plants during the summer months, and a few Russians, Lithuanians and Greeks.

All of the large plants have a “company union.” In Armour-Morris, Swifts, Cudahys’ and in Dolds there who work outside the plants during the is a variation of this known as the “50-50 club” of co-operation between the boss and the workers to increase production and eliminate waste.

In the Armour-Morris plant the retail store has been turned over to the “workers’ conference board” and they now call it the “workingmen’s store.” They sell overalls, boots and other work outfits, also products of the packing plant–the seconds, badly cut meat being disposed of in this way as it is not readily salable to the trade.

No Organization In Plants.

There is a union charter here, Local 602 of the Amalgamated Meat Cutters and Butcher Workmen, American Federation of Labor, which has about ten members, not one of whom are employed in the packing plants. This charter was that of the General Laborers’ local which had a membership of about 4,000 during the war.

This local had quite a large fund left after the last strike, which was expended in an effort to reorganize the packing house workers after the disastrous strike of 1921. The local did this without even one penny of assistance from the international union.

The I.W.W. had about 200 members after the 1921 strike, but now there is not one Wobbly left in the Omaha plants.

There was a walkout of the beef killing department at Armours last summer. The workers protested against working only 3 hours on Friday and being compelled to work 10 hours on Saturday. They demanded a half-day Saturday. The strike was lost and most of the leaders black-listed.

Strict Police System.

There is a strict police system in the plants and no worker is allowed to pass from one department to another without permission. Every policeman or “janitor’ has a key to each locker, so that there is no need to break into them for “investigation or inspection.” Most of the “janitors” in the dressing rooms are spies or secret police, but do not wear a uniform.

Then in each department there are one or more of those stoolpigeons or spies working alongside the workers. Some of them are provocateurs, starting a discussion about grievances and the need for a union; and as soon as the worker expresses an opinion favorable to a union he is reported and immediately discharged. The workers are suspicious of each other and do not talk union or grievances on the job. It is only to those blacklisted workers on the outside that they will unburden themselves.

The packing house workers never express an opinion in public, the spy system intimidates them. Altho the workers own the Butcher Workmen Hall they are afraid to go there in fear of spies; so that entertainments held there are a failure. At present the workers look upon the companies as all powerful and submit to their rule, but back in their mind is the hope that some day they will have a real fighting union, “then we will show them.” The workers are opposed to the “company union” so far as any expression can be gotten from them.

There has been a speeding up in all departments, a kind of unit cost system being used. We have been unable to get statistics on production today and what was formerly the amount. Every worker knows that the pace is much faster than formerly and that the boss in each department not only has to deal with the local plant superintendent, but with the general office as well in showing results in cheapening costs, which means more speed for the workers.

In all entertainments or picnics they split the colored and white workers, having separate places and entertainments for each group.

Draw Color Line.

At Dold’s plant they draw the color line hard, even baseball games are not permitted where white and colored play together.

They have four-minute men talk to the workers during their 30-minute noon hour on patriotism, profit sharing, co-operation with the employers, obedience to rules, etc.

There is a boy scout organization connected with the plants. Armour’s corps are taken into the plant and given entertainments, moving pictures and talks by leaders being used to teach patriotism. These entertainments are given sometimes two or three times during the week.

Unemployment All Year Round.

Unemployment and short time work prevails practically all year in the packing plants for many of the workers. There are always from 100 to as many as 400 workers looking for jobs at the gates of the large plants every morning. Some get half time or less and others only a few hours during the week. There is a great deal of uncertainty and much suffering of workers in the plants.

Rotten Sanitary Conditions.

The sanitary conditions in the plants are bad. There are 3, 4 and 5 towels placed in the dressing rooms daily to serve as many as six departments, all on one floor, as in Dolds, the most “modern” of the plants in Omaha. These towels become so dirty that the workers are compelled to use their own towels in the evening after work. Then there is but one janitor for 2, 3 and 4 toilets, which makes it impossible to keep them clean during the eight hours allowed him for this work. The lockers, too, are so small that when the clothing is placed in them they touch the clothes of the next locker.

The workers are supposed to send their working clothes to the laundry each day in a number of departments, but the wages they make do not provide the means to have the required supply of work clothes for this purpose. The workers must provide themselves with white or blue jackets and overalls and wooden shoes. When the clothes are sent to the laundry they are subjected to chemicals and terrific strain in the machines, with the result that they come back torn, full of holes and the fabric weakened. The worker puts them on and the blood and filth goes thru them into his street clothes and he returns the next day smelling of filth, a walking pest house for disease. Then again the worker is expected to change his clothes on his own time, and as the dressing rooms are small and crowded after quitting time he may have to spend half an hour to change, so this is more often neglected than otherwise. Production, not sanitation, is the keynote of the packing plants; if sanitation interferes with production, so much the worse for sanitation.

Overload Trucks.

The speed-up system results in over-loading the trucks used to transfer meat from one department to another. Often these trucks will tip over and the contents spilled on the greasy, dirty floor. With but one government inspector for each floor it is impossible to watch this, so the meat is gathered up and replaced in the truck without being washed, dirt, filth and disease being shipped broadcast as the result of the speed-up system. Some departments do not have enough trucks, and this, too, results in over-loading. Often these trucks carry a load of 1,200 pounds and are pushed by one man. Then they are never in good mechanical condition, or lubricated; this further aggravates the danger of tipping over and adds to the strain upon the worker pushing them. No worker is provided to keep them in repair or lubricated. For instance, take the trimming and “offal” departments where they have the piece-work system, the laborers serving these departments and pushing the trucks are speeded up to keep pace with the piece workers; this, too, forces neglect of sanitation. Finally, there is no protection of the workers against occupational disease, or disease aggravated by their occupation. There are many cases of diseased workers handling fresh meats daily and no attention is seemingly paid to this. to this. The only doctor’s examination given is that when the worker is first employed, and this is used mostly as a blacklist, instead of for protection of food or sanitation.

Eat Lunch in Locker Rooms.

Thirty minutes is allowed for lunch at noon. In the fertilizer department the workers’ dressing room is close to their work. The other workers object to them coming to their dressing room on account of the odors. This compels those workers to remain close to their foul smelling task during the entire day.

There is a restaurant in the plants, but service is practically limited to the office force on account of the limited time given for lunch and the necessity of staying in line during the rush period for as much as 15 minutes. The workers, especially during the cold weather, are compelled to eat their lunch in the dressing room, close to the toilet’s like cattle in a barn.

Some Pension System.

There is a pension and sick benefit plan at some of the plants. At Swifts the workers pay 54 cents per week and receive $6 minus 54 cents premium, or $5.46 per week sick benefit and $400 insurance; also a pension of half wages after 25 years continuous service. This, of course, is in effect only so long as the worker remains in the service of the company. If you “happen” to get “laid off” for a week or more your rating is lost and upon being re-employed you begin as a new employe. “Slack up and lose your pension.” During the 25-year period a maximum of 144 weeks sick benefit is allowed. During the 25 years the workers pay in $701, over which he has absolutely no control. This system is a cunning form of wage cutting. It is like the card sharper that takes your life and then hands you carfare to get to the cemetery.

The Daily Worker began in 1924 and was published in New York City by the Communist Party US and its predecessor organizations. Among the most long-lasting and important left publications in US history, it had a circulation of 35,000 at its peak. The Daily Worker came from The Ohio Socialist, published by the Left Wing-dominated Socialist Party of Ohio in Cleveland from 1917 to November 1919, when it became became The Toiler, paper of the Communist Labor Party. In December 1921 the above-ground Workers Party of America merged the Toiler with the paper Workers Council to found The Worker, which became The Daily Worker beginning January 13, 1924.

PDF of full issue: https://www.marxists.org/history/usa/pubs/dailyworker/1926/1926-ny/v02b-n302-NY-jan-05-1926-DW-LOC.pdf