Mary E. Marcy with a marvelous essay on the promise and reality of technological advancement under capitalism, where specializations that could release workers from labor only seem to enrich the bosses.

‘Advancement of the Canning Industry’ by Mary E. Marcy from International Socialist Review. Vol. 14 No. 6. December, 1913.

VERILY the age of Specialization is upon us! First it was the woolen mills that began to weave cloth and deprive woman of one of her old prerogatives in the Home. Before long we had advanced a step in specialization and boasted of butchers and packing companies. Followed bakers, restaurants, roominghouses, laundries. Steam-heated, electrically lighted flats appeared and came the day of ready-to-wear clothing.

And the canning of food products has kept step with the march of Specialization. No modern woman thinks about Monday as being Washday; Tuesday as Ironing day; Wednesday as Mending day, any more. Friday and Saturday have come to mean something besides Cleaning and Baking. The old Gods are dead! Home isn’t what it used to be; no matter what you say. If things keep on it will be clean “busted up” with all these new-fangled notions taking hold so fast.

The laundries can “do up” clothes better than Mother did, with less time and labor, and the packing companies certainly can put up a much better steak than Uncle Ezra, who lives out at the end of nowhere and is the last and only man left on earth to do his own butchering. When I spent a week with him last January I changed my mind about steam-heated flats being enervating and water half thawed from the pitcher proving invigorating for a morning wash.

I have always wanted to run one of those shuttles and work a loom and weave my own clothes, too. When Henrietta Crosman used to come out in the first act with her hair all done in little ringlets and play with a loom, at least they SAID it was a loom, I used to think they would look very pretty to have around the house. (The loom, I mean.) But when I saw some of the cloth our revered ancestors had woven on their very own, I decided it would not do at all for a dinner gown or an opera frock—if I ever was fortunate enough to have one.

I wearied of candles the night one melted all over the library table and ran down onto the rug, that belongs to our landlady. You’ll have to admit that in SOME ways things have improved a great deal.

But you see as soon people began to SPECIALIZE in one thing or another and to make just one commodity, they did it better and cheaper than other folks. By and by they used machines and hired helpers and when bigger and better machines were invented that could be operated by steam—they kept making clothes and shoes and building houses so much cheaper than anybody who was a Jack-of-all trades and Master-of-none—that men, women and even very young girls began to follow their old work into the factories and mills in order to do it in the easier way, the modern or machine way.

The Canning Industry has progressed and taken another large slice out of the oldtime Woman’s Sphere. And we have to grant that things can be accomplished, food can be cooked, bread baked, cloth woven, with less human labor-power under the specialized, machine method than the individual could do in the old haphazard way. We can get better clothes, better food, better homes—better everything today—or rather we can if we have money enough. Some day things will be different, but that’s another story.

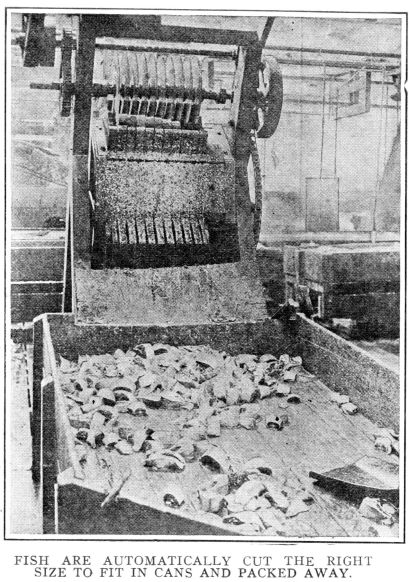

The scientific preserving of food has its basis in the work of Pasteur, but even in 1819 an Englishman had a canning factory in New York City for packing lobsters, salmon and oysters, and in 1825 fruits and vegetables were canned. Glass jars were used in the early days, but excessive breakage led to the use of tin cans. At first the edges of the cans were butted and the ends soldered.

Gradually, however, machinery was developed for can making and today the production of tin cans from tin plates is automatic and continuous and most canning companies have their own can-making plants.

The old vacuum theory which held that it was only necessary to exclude the air to prevent the spoiling of food has long been exploded, except in preserving jams, meats, salt, etc.

Pasteur was the first man to associate spoilage with organisms and, in time, canners began to understand that these bacteria could be killed off at a certain high or low temperature, and new ideas on scientific canning soon prevailed.

In modern canning factories the heat or cold used to preserve foods is regulated automatically by clocks that shut off steam or cool air when the necessary temperature has been attained. Last year, 168 million cans of peas were packed by automatic machinery; 336 million cans of tomatoes and 312 million cans of corn.

Modern pea harvesting is now done entirely by machinery, the vines being cut about the same way as hay. Special machines called viners handle the cuts, removing the peas from the pods by beaters. The peas fall through perforations in a cylinder large enough to allow them to pass through but which retain the vines, pods, etc. Then the peas are washed in cold water in a revolving squirrel cage. These cages are perforated in sections with different sized holes, varying from nine thirty-seconds to twelve thirty-seconds of an inch, the–latter being called “early June peas.”

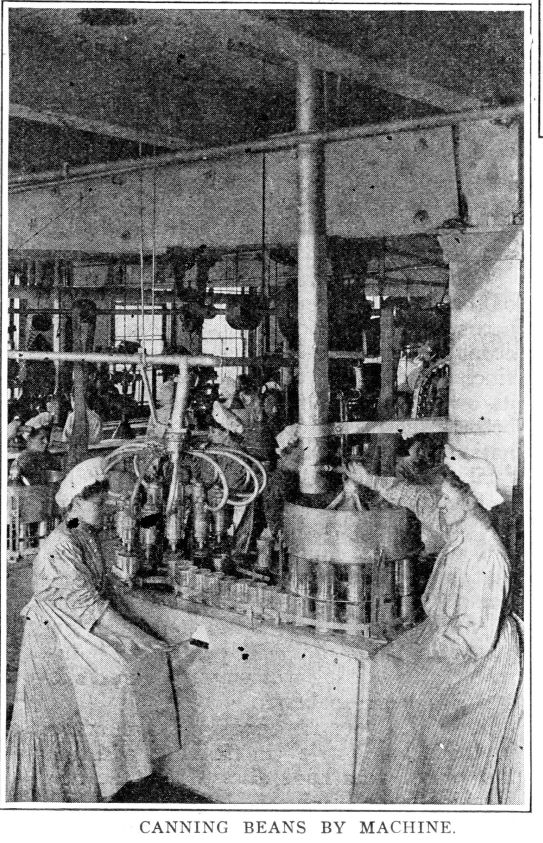

Other packers grade peas by their density, skimming off the different grades each of which will float in a certain solution of specific gravity. When the peas are washed and blanched they go to the filling machines where they are automatically filled into cans, salt and sugar being added at the same time.

The cans are capped by machinery, heated in retorts to kill off all bacteria, cooled and sent to market.

Canned and preserved food will be one of the staples of the new century. We are becoming more and more crowded in our economic functions. The time has long since passed when each family can rely on its own food resources. Canned food will become the great food reserve fund of the nation, the necessary national storage for facilitating supply to demand.

The demand for canned food is a natural one. Canning has left the home and gone into public life quite for the same reasons that boot-making and weaving and other fine old “home activities” have become public utilities. Canning is no longer a “domestic industry,” but it is one of the industries that is making women wage-earners instead of home-makers.

It is the very cheapness of production in foods and “style” in clothing, added to low prices, that have always sold the new machine-made products. Women have followed their old labors into the factories and mills. There is nothing to regret in the new methods of Specialization. No intelligent human being wants to return to candles or home dyeing and weaving; to the splitting and sawing of wood for the daily breakfast; to home butchering, lard rendering, candle-making that made the old “free days” continuous arduous toil from three or four in the morning till late at night three hundred and sixty-five days in a year.

We want to make use of all modem machinery and modern methods of production for the benefit of the human race. We want to plan so that the Machines will do ALL the disagreeable and heavy work. Division of labor is making wonderful changes in the old-time home, relieving, as it does, our women from the burden of domestic hand labor.

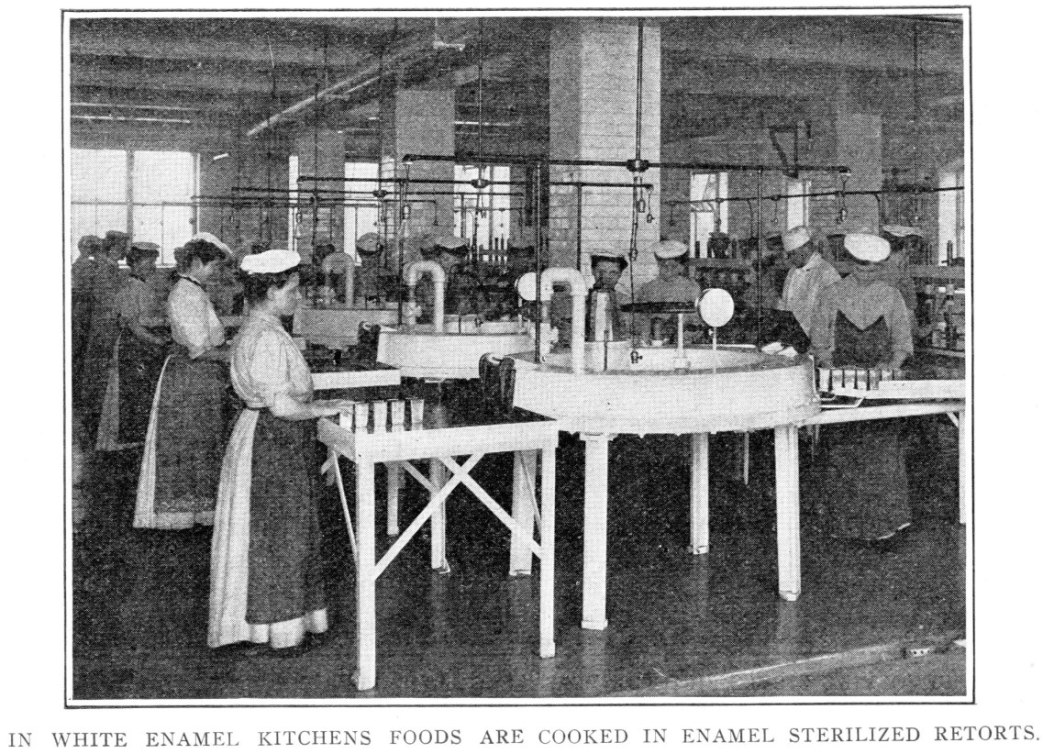

In the new and modern canning factories all retorts are made of copper, brass, enamel or silver. Floors are of concrete and tables have glass or snowy enamel tops. In twenty minutes entire floors may be cleaned by turning on the hose. These great canneries resemble nothing so much as a surgeon’s operating table.

The juice is extracted from trimmings not used in canning and used for fountain syrups. Apple cores and peelings are sold for wine and vinegar, sometimes for cider.

Fruit parings or peelings often make a cheap grade of jellies and apple “waste” is the basis for the compound jams.

Corn silk is saved and used for medical purposes. Seeds from tomatoes, and pumpkins, stones from cherries, plums and peaches are used for oil. Nothing is wasted any more.

Most of us look with horror on any but a new-laid egg with an unbroken shell, and a guaranteed date thereon. The phrase, canned eggs, brings to our minds a horrid picture of a yellow, evil-smelling mess used by some of the most profit-mad bakers. Yet the time is coming, we are advised by the U.S. Bureau of Chemistry, when the canned egg will be with us as familiarly as the storage egg and far more acceptably. To can the eggs in times and localities of plenty while they are strictly fresh is the big thing. According to the Department: “In a sterilized room we will have the canners dressed in white, their hands made surgically clean. Before each girl will be a tray of eggs at exactly the right temperature for canning. Perfect eggs will be dropped into sterilized jars which will be sealed.” Yes, strictly “fresh, canned eggs” will be next, they tell us.

The International Socialist Review (ISR) was published monthly in Chicago from 1900 until 1918 by Charles H. Kerr and loyal to the Socialist Party of America and is one of the essential publications in US left history. During the editorship of A.M. Simons it was largely theoretical and moderate. In 1908, Charles H. Kerr took over as editor with strong influence from Mary E Marcy. The magazine became the foremost proponent of the SP’s left wing growing to tens of thousands of subscribers. It remained revolutionary in outlook and anti-militarist during World War One. It liberally used photographs and images, with news, theory, arts and organizing in its pages. It was closed down in government repression in 1918.

PDF of full issue: https://www.marxists.org/history/usa/pubs/isr/v14n06-dec-1913-ISR-riaz-ocr.pdf