Mass production and the end of the ‘skilled’ worker employed in the building of rail cars.

‘The Revolution in Car Building’ by Paul L. Wright from International Socialist Review. Vol. 15 No. 6. December, 1914.

AS the huge steel car goes swiftly gliding by, few people realize the enormous and wonderful change that has taken place in the car building industry. Formerly built almost entirely by domestic craftsmen, the grand Pullmans, dining cars, and the elegant day coaches of today are now built almost entirely by foreign labor. From the time the ore is unloaded at the steel mills until the finished product is turned over to the railroad companies to do service, alien labor predominates over domestic ten to one. Since, generally speaking, foreign workingmen have always been synonymous with unskilled labor, it is apparent that in this industry the day of the skilled woodworker is over. Never again will his services be needed. As the smooth steel glides through the huge rollers in the mills, so does the opportunity for the skilled woodworker to live by his handicraft, glide to oblivion. And this marvelous revolution has taken place in the short space of seven years.

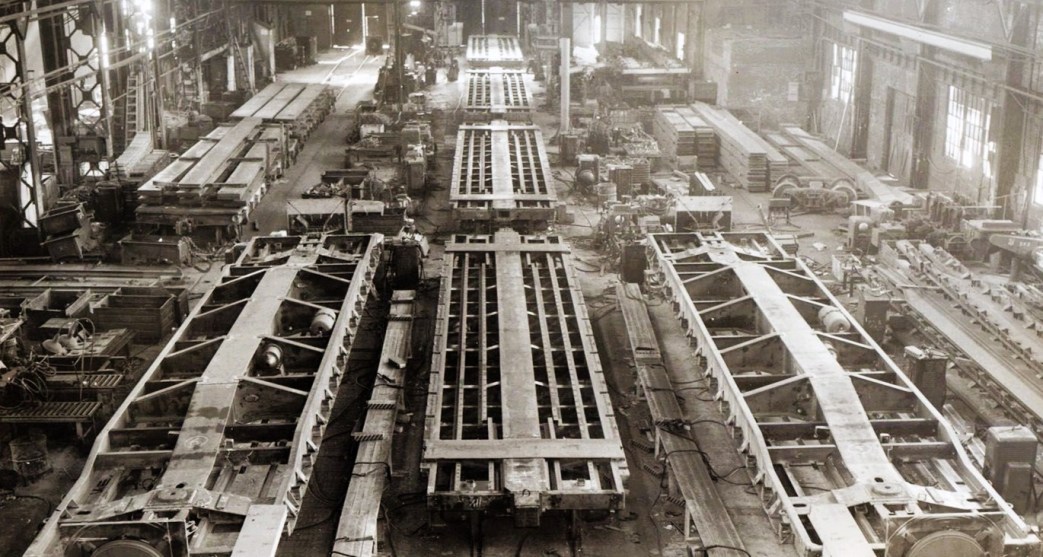

We will now consider the steel car in its first stage of construction. Great center sills are lifted into place by gigantic cranes which run on a track near the roof of the building. These cranes span a space of almost one hundred and fifteen feet and can travel from one end of the building to the other carrying with them any piece of steel that may be needed at the far end of the shop. Within this huge crane there is another, a small car that can run on the crane and crossing the span, can pick up a piece of steel and carry it to the other end of the span. These cranes are operated by a single operator and a hook-on man, whose duty it is to fasten the chain to whatever needs to be transported.

With the first piece of steel in place we will now pass on to the next operation, which is the riveting of the side stills and cross beams to the great center sill. Workmen with great air hammers, called bull riveters, which are suspended by portable cranes, drive the cherry-hot rivets and securely fasten the foundations of the car. The framework being completed, the side plates: and the roof sheets are now bolted fast and another gang of riveters drive the sides, roof and ends.

What effect has this operation had on the woodworker? If the car had been constructed of wood as in former years the services of the lumberman, saw mill operators and carpenters would have been required, but as it is of steel construction, their labors have been entirely dispensed with.

The body of the car completed, it is ready to be taken to the sandblast. Perhaps some of you will wonder what a sandblast is.

Sandblasting is to the steel car what planing and sandpapering is to the wooden structure. If you want a board for the top of your library table you would desire it smooth arid to get it so it would have to be run through the planing machine and a sandpapering machine. Just so with the steel car. To get the sides of the required smoothness they must be sandblasted, but this process is much simpler and less expensive than the methods used by the woodworker, for the tools need no knives sharpened nor do the gears wear out. Hence valuable time is also saved.

No doubt some of you would like to know what a sandblasting tool is like. It consists of a piece of hose attached to the air line (compressed air in pipes). To the end of this hose is fastened a pipe; this pipe is joined by another hose three or four feet from the end, the loose end of which is dropped into the sand box. The compressed air is then turned on and as it rushes through the long hose the suction draws the sand up through the short piece and hurls it with terrific force against the sides of the car, reducing the lumps and irregular spots to a common smoothness. The operator has only to move the hose from place to place as it is needed. The car is now ready for interior finishing.

In this department let us take notice of the revolutionary processes which make up the interior finish. The first process to be considered is the making of steel molding. We see a thin, narrow steel band being pulled through a die by a long chain driven by electric motor power. It reaches out over a narrow table probably ninety feet in length, the chain slowly traveling to the far end of the table and with it the finished piece of hollow molding. It is made in this manner into car lengths. By pulling the molding into car lengths the process of installing it in the car is greatly simplified. As most steel cars are approximately seventy feet long, it would require the services of a skilled woodworker to join the various lengths whereas the work is now done without piecing, again saving valuable time and money and labor as well as increasing the efficiency.

Almost everyone has noticed how a wooden door is constructed, the outer pieces being made with a groove cut on the inside to receive the panel. With the steel panel the outside pieces are pressed or pulled and the panel then inserted. There follows another process called electric spot welding. The panel is taken to the welding machine and placed in position. The operator turns a lever and between the points of contact a bright red spot appears. The lever is then thrown back and the material moved into another position, the operation being repeated until the pieces are securely fastened together. All this requires only a few seconds’ time and is much more efficient than the process of wooden door making.

Acetylene gas welding is another process steel undergoes. This is used to weld roof seams, fill holes, join window sashes, cut steel and a thousand other different things peculiar to steel car building. It is one of the most useful inventions used in steel car manufacturing.

Arc welding is another electrical contrivance which is being perfected and at a future day more may be said of its effectiveness. It has been tried and proven quite a success.

The material for the interior finish now completed, we will make ourselves acquainted with the methods and tools used to install this in the cars. There are holes to be drilled and reamed. Right here is where the superiority of modern tools over the self-propelled tools of the woodworker is most remarkably demonstrated. The Dunt ley Electric Company manufacture a small electric motor which is a most handy little machine. Made with a handle at one end and at the other one chucks of different styles to hold any shaped drill or reamer, one man can drill more holes with one of these machines in one hour than a workman with the old-fashioned brace and bit could drill in one whole day.

Another machine which does heavier and more difficult work is the air drill. Manufactured by the Thor Machine Company, this machine is built in all styles and shapes of various capacities. These last two-named machines have entirely removed the skilled woodworker and his simple hand tools to other fields of employment or to discardation and unemployment.

When the car has received its interior finish, another modern process takes place. The new monolith floor is laid. A monolith floor is made of wood pulp and fibres mixed with certain kinds of acids and chemical compounds to make the mass a solid piece of work after being laid. Allowed sufficient time for drying this makes a beautifully smooth and attractive floor much superior in looks and wearing qualities to the old style wooden floor.

The car is now ready for painting and trimming. After it is striped, grained and varnished it has the appearance of a solid steel house on wheels, a veritable palace, surely a great and grand improvement over the old-time wooden passenger car in appearance alone. And when its efficiency and wonderful life-saving qualities in time of wrecks or collisions are taken into consideration, why grieve and mourn that this indestructible modern instrument of travel has ousted the skilled woodworker from plying his trade in this line even for all time to come? Through all the ages it has ever been the survival of the fittest. Modern improvements, inventions and discoveries are the culmination of human desires and endeavors. Every new commodity that is produced cheaper and better has a more certain chance of success over others not possessing these qualities.

New inventions and processes promote the welfare of certain groups in society. While one group of workers are employed that have skill in the manufacturing of certain things, others are unemployed because their skill is a lost art, relegated to uselessness by inventions and more efficient methods of production. This has been the case of the wooden car worker.

The irresistible laws of Capitalistic Society work in cycles of death to some and birth to others. Never will the welfare of the workers be secured so long as the capitalist régime holds sway.

To be a successful mechanic or inventor one must act in accordance with the laws of mechanics or physics and success in our endeavors depends upon and is facilitated only by knowledge and observance of these laws. Inform yourselves of the economic, industrial and social laws and sciences and profit by adapting yourselves to these great truths. Knowledge means solidarity and solidarity means independence and fulfilled hopes, the realization of which have long been deferred and almost crushed by the cruel forces of capitalism.

The working class must understand the intricate and complex laws of capitalistic society and render them void and useless by voting to own the tools of production and distribution collectively, thereby causing each new invention and process to benefit the whole of society instead of a small proportion. Then only will we truly live instead of merely exist.

The International Socialist Review (ISR) was published monthly in Chicago from 1900 until 1918 by Charles H. Kerr and critically loyal to the Socialist Party of America. It is one of the essential publications in U.S. left history. During the editorship of A.M. Simons it was largely theoretical and moderate. In 1908, Charles H. Kerr took over as editor with strong influence from Mary E Marcy. The magazine became the foremost proponent of the SP’s left wing growing to tens of thousands of subscribers. It remained revolutionary in outlook and anti-militarist during World War One. It liberally used photographs and images, with news, theory, arts and organizing in its pages. It articles, reports and essays are an invaluable record of the U.S. class struggle and the development of Marxism in the decades before the Soviet experience. It was closed down in government repression in 1918.

PDF of issue: https://www.marxists.org/history/usa/pubs/isr/v15n06-dec-1914-ISR-riaz-ocr.pdf