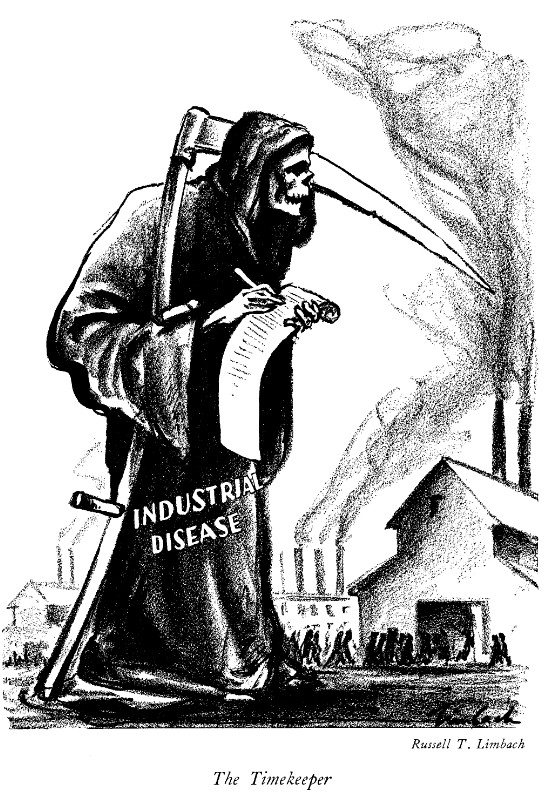

The Daily Worker’s labor editor on the toxic stew of chemicals in an auto plant, with a particular focus on lead poisoning.

‘Workers Poisoned in Auto Industry’ by George Morris from Health and Hygiene. Vol. 3 No. 4. April, 1936.

HOSPITALS of Detroit, Flint and other automobile centers are receiving every week hundreds of victims of lead poisoning, the most widespread and serious industrial plague. While lead-poisoning is one of the oldest known occupational diseases, it is only during the past year or two that it received attention as a serious menace in the automobile industry.

What caused this sudden spurt in the number of victims of lead poisoning? How widespread is the plague? How is the disease met by the plant management? Are the present labor laws adequate to meet the menace?

As I searched for an answer to these questions I learned of an almost unbelievable situation. The employers are doing everything possible to hide the facts while government and health authorities are shutting their eyes to the situation. To make matters still worse, leading hospitals in almost all cases are especially favored by certain of the large automobile companies and often have an agent on the hospital boards of directors.

While there are no statistics available on the extent of lead poisoning we do have the recent findings of a committee headed by Dr. Carey McCord, of the industrial Health Conservancy Laboratories of Cincinnati, gathered in its investigation during the 1934-35 automobile production season. The findings, based on research while they were engaged by the automobile companies in Detroit, were presented to the 66th Convention of the American Public Health Association. The committee estimated that about 4,000 workmen have been injured by lead poisoning during the 1934-35 production season.

This, however, is undoubtedly only the number that required hospital treatment, or have become disabled for factory work. Several weeks ago I learned through one who is closely associated with three lead-poison laboratories maintained in the plant of the Briggs Body Corporation, that since the laboratories have been established, about a year ago, there are on file almost 13,000 blood tests taken among the employees of the plant, that show considerable amounts of lead absorption by these workers. We will see later why a majority of these were neither warned of the threatened disease nor given treatment.

McCord’s Committee in its report explained the causes of the great increase in lead poisoning as follows:

“The automobile production season of 1934-35 marks the outstanding epidemic of lead poisoning in this country for at least the past decade.

“Recent trends in body design have led to one-piece all-metal bodies with non-air-resisting contours. The manufacturing processes call for the filling in of all welding depressions and other indentations with a lead-tin alloy. This leads to the use of molten lead pots and torch work, which in turn are followed by various processes for the smoothing down of the leaded surfaces, including power grinding, hand filing, sanding, etc. As a result, the atmosphere of these workrooms is polluted by harmful quantities of lead-dust and lead-fumes. Occasionally as much as 1,100 milligrams of lead dust have been encountered in 10 cubic meters of air, which amount of air approximates the quantity of air breathed by the average workman during the usual work day.”

And further:

“If the figures obtained in studies in a limited number of plants may be extended to the industry as a whole, it is possible that as many as 4,000 workmen have been injured to some extent during the 1934-35 automobile production season.”

So when you admire that nice smooth finish on present-day bodies, you may also picture to yourself a workroom filled with lead dust, and workmen who eventually begin to get severe pains in the abdomen, headaches, vomit, get dizzy, constipated, anemic, weak, nervous, and who are finally forced to give up.

SO large is the number of lead poisoned cases that companies deal with hospitals on a “mass production” scale. A larger number of mild cases are treated at plant hospitals. There is a certain section in St. Mary’s Hospital where a batch of victims will always be found. They are from the Briggs Corporation, largest automobile body maker. The patients are treated only by a special Briggs doctors. Only the company knows anything of their cases. A patient is kept in the hospital for two or three weeks, usually given injections, pronounced well, and put back to work.

Physicians who frequently get cases of lead poisoning explained to me that the patient must get treatment and complete rest for at least two months, sometimes as much as six months and longer. It takes that long to drive the lead out of the system. In fact one is never completely cleared of lead. Lead victims must never get near jobs that again expose them to lead as they are very easily susceptible to further poisoning.

As the companies are obliged to pay up to $18 a week sick benefit to poison victim during hospitalization, the doctor rushes them through. They are often returned to jobs in other departments, away from lead, but the worker is unable to last long, or do his work efficiently. He either leaves the job in disgust, or is laid off at the first opportunity.

A talk with various lead poison victims soon illustrates how the scheme works.

“This is the third time they have me here,” a thoroughly disgusted Polish worker in St. Mary’s told me. “After being here two weeks, the company doctor said I was O.K. When I got back to work the foreman told me he doesn’t want lead poisoned people.

“They put me on an outside job. After working a day I got my dizzy spells again and stayed in bed for three days. Afraid to lose my job I went back to work, but I couldn’t last more than a day, and they sent me to the hospital again.

“I don’t know what will happen next. But I know what you’re just no good any more after you get lead into yourself.”

Another worker in the same room told me he lost over 30 pounds since he began to feel the effects of lead. He just dropped on the job one afternoon. “I saw eight go on my floor, taken with lead, since we started this season” (October), he said to me. “And it got me too.”

An old Finnish worker who worked as a metal finisher at Briggs has been in St. Mary’s Hospital for over six months, I was informed. He is a case of chronic lead poisoning and has apparently contracted other ailments due to that condition.

In the hospitals the workers are kept under as much discipline and observation as in the plant. For fear of losing the $18 a week or the chance to get back on a job, patients dare not protest or talk against the company. I was particularly struck by the prison atmosphere in the section of the hospital where the Briggs victims are.

Many lead poison victims become serious medical problems. In some cases lead affects the brain, resulting in mental disorders, including insanity. Some get convulsions, become nervous wrecks or paralyzed. These are, of course, the most severe manifestations of lead poisoning.

Charles Somal, who was once a healthy metal finisher at the Dodge plant, is today in Eloise Hospital for the insane. His mental derangement was a development from chronic lead-poisoning, according to a diagnosis which was made at the Harper Hospital where he was first sent.

But we must take into account more than the direct effects of lead-poisoning. Victims of lead poisoning are not restored to full health. They become changed people, considerably weakened, and an easy prey to other diseases. Thus, while we do not hear of many deaths directly due to lead-poisoning, many who die begin their ill health with lead-poisoning. The doctor, of course, makes out a death certificate only according to the apparent cause of the death.

BUT perhaps the most serious feature is the way the employers met this lead-poisoning epidemic. The manufacturers are certainly interested in doing something about the situation, because the plague proves very costly to them. Furthermore, they fear that if the seriousness of the disease becomes too apparent they will

not be able to hold off legislation that will make them liable to disability compensation for industrial diseases in general.

They have therefore engaged the staff of Dr. McCord who is regarded as an expert on lead-poisoning. McCord has used a blood test to determine the lead content in the blood. It is known as the Basophilic Aggregation Test. The above-mentioned report, submitted to the American Health Association Convention, was

mainly based on the experience with this blood test concluded from 8,000 tests in the industry. The test is based on the theory that lead absorption destroys the red blood cells. The relative change in the blood therefore can also indicate the approximate amount of lead absorbed. Lead-exposed workers are, therefore, forced to take blood tests often; in the Briggs plant every month.

Early detection of lead absorption is an advantage because the worker can be warned in time to take treatment, and hygienic experts are able to locate the danger spots in a plant. But to the company there is a much more important advantage. The blood test shows to the company the approximate dead-line the time when the worker should be discharged so that he won’t get sick while still in the employ of the company; thus, the company does not have to pay him sick benefit and stand his hospital expense.

Having instituted lead laboratories at the Briggs Corporation, the staff of Dr. McCord is now employed at the Dodge plant. Today only those get sick on the company’s hands whom the test does not catch. The plant is notorious for its frequent hiring and firing.

But cheating and discharging workers is only half the story. Admittedly the test is by no means perfect. The result is that many who are developing lead-poisoning are missed. On the other hand the worker knows nothing of what the test shows. All he knows is that one fine day, in a week or two, he is “laid-off.” Instead of taking treatments the worker is out searcing for another job. If he is so “fortunate” as to get a lead-exposed job soon, it isn’t long before he becomes a serious case. To avoid employing workers for whose sickness another employer is responsible, a blood test is taken of metal finishers when they are being hired.

THE state government took little cognizance of the situation. The 1935 Michigan Legislature again turned down a proposal to include occupational diseases in the present Workmen’s Compensation Law. The Supreme Court ruled that lead is absorbed “gradually, so it isn’t an industrial accident.”

The U.S. Department of Labor in Michigan has neither the interest nor the facilities for proper inspection of the plants so as to at least enforce existing inadequate laws. There are laws providing regulation of air in a plant, fans, dust-collectors and other safeguards. At the Detroit office of the Department of Labor and Industry, I was informed that there were only two men to inspect the plants in the entire industrial area of the city and county.

Recently some improvements were instituted. Power grinding was substituted by hand filing. This process does not create as much lead dust. But the fumes caused by the torch-soldering remain as before. Significantly, the best improvements were made at the Chrysler plant, where the workers are organized to some degree and have fought out the issue.

These improvements, however, are only a soothing salve. So serious has become the issue of compensation for occupational diseases and of more adequate protection, that the manufacturers are in fear of laws that will prove far more costly in the long run.

It should also be mentioned here that lead poisoning is only the most widespread occupational disease in the automobile plants. The industry also contributes a large number of victims of silicosis and of many other diseases due to chemicals used in the painting of cars, treating of metals, and so forth.

There is perhaps no other industry that throws off as many human wrecks as the automobile and auto-parts industry. If lead-poisoning and other industrial diseases of the automobile industry were recognized legally as compensated occupational diseases, there would be at least a small degree of repayment for the destruction of health and life.

Health was the precursor to Health and Hygiene and the creation of Dr. Paul Luttinger. Only three issues were published before Health and Hygiene was published monthly under the direction of the Communist Party USA’s ‘Daily Worker Medical Advisory Board Panel’ in New York City between 1934 and 1939. An invaluable resource for those interested in the history history of medicine, occupational health and safety, advertising, socialized health, etc.

PDF of full issue: https://www.marxists.org/history/usa/pubs/health/v3n4-apr-1936-health-hygiene.pdf